Innovative Manufacturing Techniques: In-Mold Decorations Explained

Innovative Manufacturing Techniques: In-Mold Decorations Explained

Blog Article

Grasping In-Mold Decorations: Strategies, Patterns, and Finest Practices for Optimum Results

In the world of manufacturing, the art of in-mold designs stands as a critical facet of item layout and production. In-Mold Decorations. By diving into the strategies, patterns, and finest practices that underpin effective in-mold design procedures, companies can unlock a world of possibilities that not only raise the aesthetic appeal of their items but also improve production performance and reinforce consumer involvement.

Product Option

Product selection is a crucial aspect of understanding in-mold decors, as it directly impacts the quality and toughness of the final item. When choosing products for in-mold decors, it is important to think about aspects such as compatibility with the molding process, the desired aesthetic outcome, and the environmental problems the item will certainly encounter.

Furthermore, the chosen product should possess excellent bond homes to ensure that the decor adheres strongly to the substrate throughout the molding procedure. Bond between the design and the product is important for stopping delamination and making sure lasting aesthetic charm. Furthermore, materials with high warmth resistance are favored for in-mold designs, especially for products that will be subjected to elevated temperatures during their lifecycle. By meticulously choosing the proper product for in-mold decorations, manufacturers can enhance the general high quality and sturdiness of their items, meeting the assumptions of both end-users and customers.

Design Advancement

An important element in advancing the area of in-mold decorations is the continuous exploration and application of layout innovation techniques. Layout advancement plays an essential function in boosting the visual charm, capability, and general high quality of products manufactured utilizing in-mold decoration procedures. By including innovative style components, suppliers can differentiate their products in the market, bring in consumers, and remain ahead of competitors.

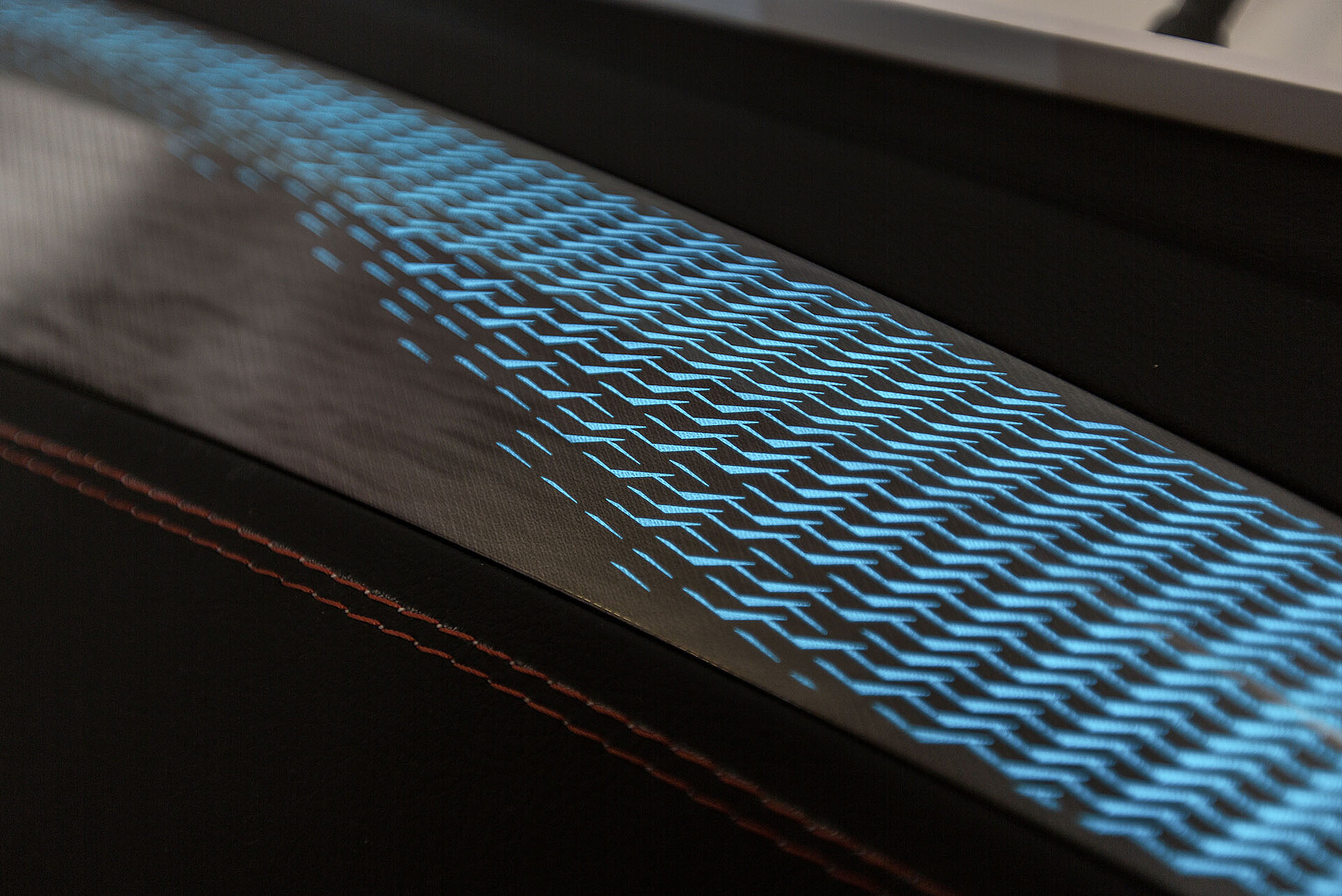

Among the key facets of layout innovation in in-mold decorations is the integration of detailed patterns, structures, and graphics that were formerly testing to attain with conventional decoration methods. Advanced modern technologies such as 3D printing and digital layout tools enable designers to create complex and detailed layouts that can be flawlessly transferred onto molded components. In addition, using dynamic shades, metallic finishes, and unique effects like gloss or matte appearances can even more raise the aesthetic allure of in-mold enhanced items.

Additionally, design technology expands beyond aesthetic appeals to incorporate functional improvements such as ergonomic forms, incorporated functions, and customizable aspects that satisfy specific individual requirements. By welcoming design innovation, manufacturers can unlock brand-new possibilities for product, customization, and creative thinking distinction in about his the affordable landscape of in-mold decorations.

Production Effectiveness

Reliable manufacturing procedures are essential for translating the cutting-edge styles created in the area of in-mold designs into top notch completed products that satisfy market demands and consumer expectations. In the realm of in-mold decorations, manufacturing effectiveness incorporates various crucial facets that add to the overall success of the production process.

In addition, carrying out automation and robotics in the assembly line can dramatically improve effectiveness by improving repeated jobs and minimizing the margin of mistake. Automation not just accelerates the production site here process yet additionally enhances accuracy and repeatability, causing an extra premium and consistent final result. Embracing lean production principles, such as just-in-time stock administration and waste reduction methods, can further enhance manufacturing effectiveness by minimizing downtime and enhancing resource utilization. On the whole, an all natural strategy to production performance is extremely important in optimizing the capacity of in-mold decoration techniques and attaining optimal lead to the open market landscape.

Top Quality Control Procedures

What are the crucial approaches for guaranteeing strict top quality control measures in the world of in-mold decors? Quality control measures are extremely important in in-mold decor procedures to make sure the manufacturing of high-quality and flawless finished products.

Utilizing sophisticated innovations such as computerized inspection see it here systems can additionally improve the quality assurance process by giving accurate and trustworthy data for analysis. These systems can detect flaws that may be missed out on by hand-operated inspections, thus improving general item high quality and consistency.

Routine training and development programs for staff members entailed in the in-mold design process can also add to preserving top notch requirements. By enlightening staff on ideal techniques, top quality expectations, and the significance of interest to detail, business can cultivate a society of quality awareness throughout the organization.

Consumer Allure

To enhance the bankability of in-mold decoration products, comprehending and providing to customer choices play a vital duty in identifying their appeal and success. Offering personalization options such as personalized styles, shade variations, and textural elements can significantly enhance the charm of in-mold decoration products.

Verdict

In-mold decors provide a efficient and flexible way to improve item looks. Grasping in-mold decors requires a holistic method that considers all facets of the manufacturing process to ensure success.

In the world of production, the art of in-mold decors stands as a critical element of item design and manufacturing. Layout innovation plays a vital role in improving the aesthetic charm, functionality, and general top quality of items produced using in-mold design processes.One of the essential facets of layout advancement in in-mold designs is the integration of intricate patterns, structures, and graphics that were previously challenging to achieve with typical decoration approaches.Reliable manufacturing procedures are crucial for equating the cutting-edge designs created in the area of in-mold decorations right into top notch ended up items that fulfill market needs and consumer expectations. Supplying customization options such as tailored styles, color variations, and textural components can substantially boost the allure of in-mold decoration products.

Report this page